4H-SiC Powder: The Core Foundation of Third-Generation Semiconductor Materials and Industrial Innovation

1. Definition and Technical Characteristics of 4H-SiC Powder

4H-SiC (4H-Silicon Carbide) is a hexagonal crystal system wide-bandgap semiconductor material. Its unique crystal structure (alternating ABAB stacking of carbon and silicon atoms) endows it with exceptional physical properties. Compared to other polytypes (e.g., 3C-SiC, 6H-SiC), 4H-SiC exhibits a wider bandgap (3.26 eV), higher electron mobility (~1000 cm²/(V·s)), and superior resistance to high-temperature and high-pressure environments, making it indispensable in applications such as new energy vehicles, photovoltaic inverters, and 5G communications.

Key technical advantages include:

- High thermal conductivity (4.9 W/cm·K) and breakdown electric field strength (2–4 MV/cm), enabling reliable operation under extreme conditions.

- Low thermal expansion coefficient and chemical inertness, ensuring long-term stability of devices.These characteristics position 4H-SiC as a critical material for power electronics (e.g., SiC MOSFETs, IGBTs) and radiofrequency devices (e.g., GaN-on-SiC).

2. Synthesis Methods and Technological Innovations

2.1 Main Production Approaches

Industrial-scale 4H-SiC powder production primarily relies on:

- Physical Vapor Transport (PVT): Silicon carbide raw materials sublime at 2000–2240°C, with gaseous components depositing on seed crystals. This method requires precise control of temperature gradients (2100–2240°C) and pressure (5–40 mbar) but faces challenges in crystal defect reduction.

- Self-propagating High-temperature Synthesis (SHS): Utilizes exothermic reactions between silicon and carbon powders (Si + C → SiC). While cost-effective, optimizing raw material ratios (Si:C = 1:1.1) and inert atmospheres (argon protection) is critical to avoid impurities.

2.2 Emerging Techniques

Recent advancements focus on:

- High-Temperature Solution Growth (HTSG): Introducing rare-earth oxides (e.g., CeO₂, Y₂O₃) as solvents lowers growth temperatures (1600–1800°C) and improves crystal quality.

- Microwave and Spark Plasma Sintering (SPS): Rapid heating (1000–10,000°C/min) shortens processing cycles but demands advanced equipment.

3. Applications and Functional Roles of 4H-SiC Powder

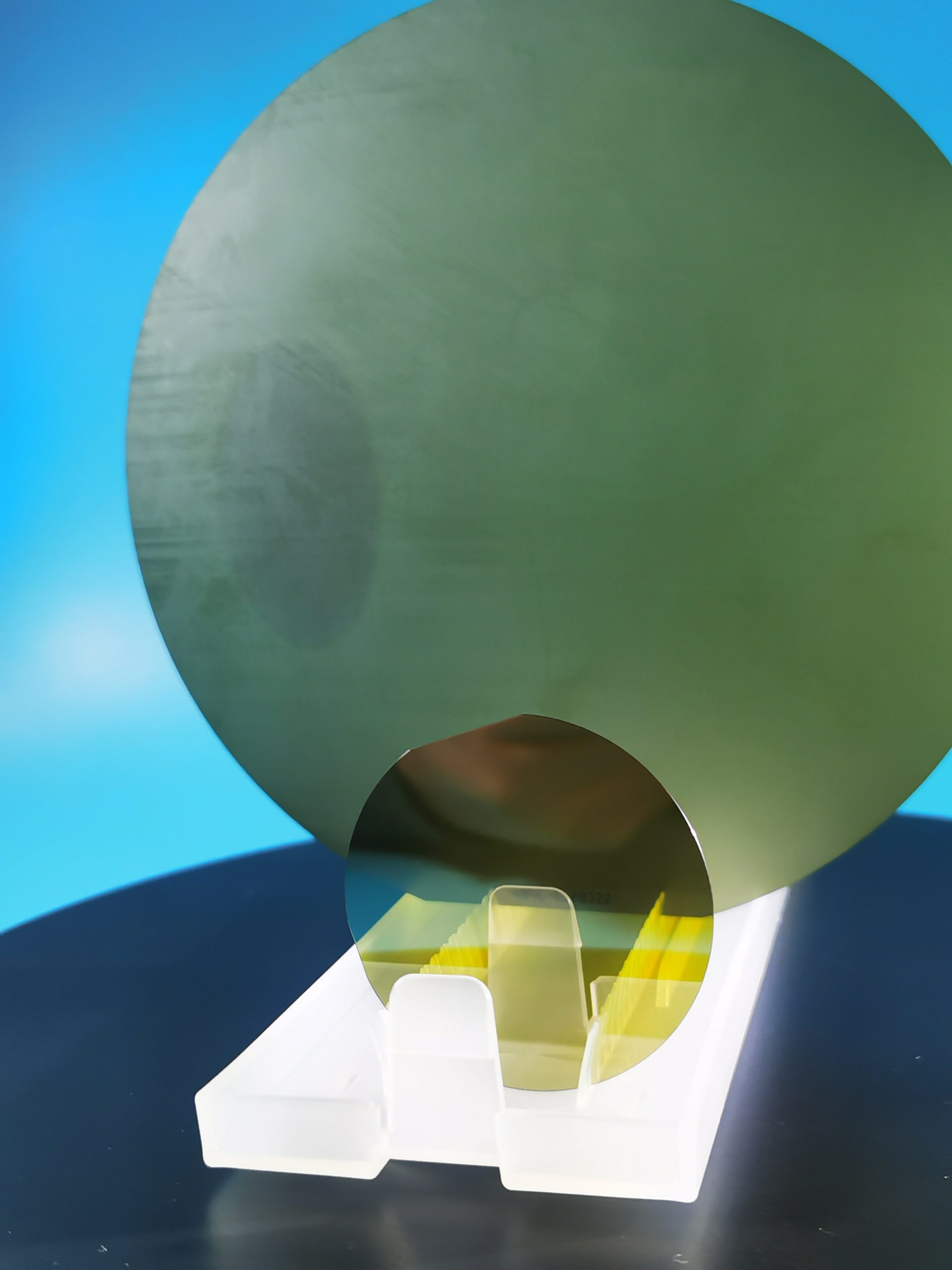

3.1 Substrate Manufacturing

4H-SiC powder serves as the precursor for 4H-SiC single-crystal substrates. High-purity (>99.999%) powder minimizes crystal defects (e.g., micropipes, dislocations), enhancing substrate yield. For example, Tianke Qianjie improved 8-inch substrate resistivity to 7–12 mΩ·cm through optimized synthesis, reducing device conduction losses.

3.2 Power Electronics

- Electric Vehicles: 4H-SiC MOSFETs achieve 97% efficiency in 800V drivetrains, as adopted by Tesla Model 3.

- Photovoltaic Inverters: SiC modules boost switching frequencies to >100 kHz, reducing volume by 50% (e.g., Huawei, Sungrow Power).

3.3 RF and Optoelectronics

- 5G Base Stations: 4H-SiC-based GaN RF devices deliver >10 W/mm power density for millimeter-wave communication.

- UV Photodetectors: 4H-SiC achieves 0.1 A/W responsivity in aerospace applications.

4. Market Trends and Pricing Dynamics

4.1 Supply-Demand Landscape

In 2024, the global 4H-SiC substrate market exceeded $2 billion, with China accounting for >30%. Leading manufacturers like Tianyue Advanced Materials and Tianke Qianjie produce >500,000 8-inch wafers annually, though high-end products (e.g., low-resistance P-type) still rely on imports.

4.2 Cost Drivers

- Raw Material Costs: High-purity SiC powder (>99.9999%) costs $500/kg, representing 40% of substrate expenses.

- Process Complexity: 8-inch substrates face ~60% lower yields than 6-inch versions.

- Supply Chain Stability: Graphite crucibles and hard felts account for 20% of equipment costs; domestic alternatives are reducing expenses.

5. Future Directions and Challenges

5.1 Technological Synergies

- Liquid-Phase Hybrid Methods: Combining liquid-phase synthesis with PVT could reduce defects and accelerate growth rates.

- AI-Driven Defect Control: Machine learning optimizes growth parameters, cutting dislocation density from 10⁴ to 10² cm⁻².

5.2 Industrial Barriers

- 12-Inch Substrate Mass Production: Only Tianyue Advanced Materials has achieved small-scale trials, hindered by thermal field uniformity and seed compatibility.

- Cost Optimization: Reducing powder synthesis energy consumption by 30% and scaling production to lower depreciation costs are critical.

Conclusion

As the “industrial staple” of third-generation semiconductors, 4H-SiC powder’s innovation and cost control directly impact downstream competitiveness. With the explosive growth of new energy vehicles and AI chips, the 4H-SiC substrate market is poised for a golden era. Through process breakthroughs and supply chain collaboration, China is set to dominate global SiC production.

6 inch N-type SiC Substrate – Product Specification 8Inch 200mm 4H-N SiC Wafer Conductive dummy research grade 2 INCH HPSI High purity 4H-N Silicon Carbide Wafer Type 330um SiC Crystal Wafers Ingots xinkehui|提供优质晶圆衬底