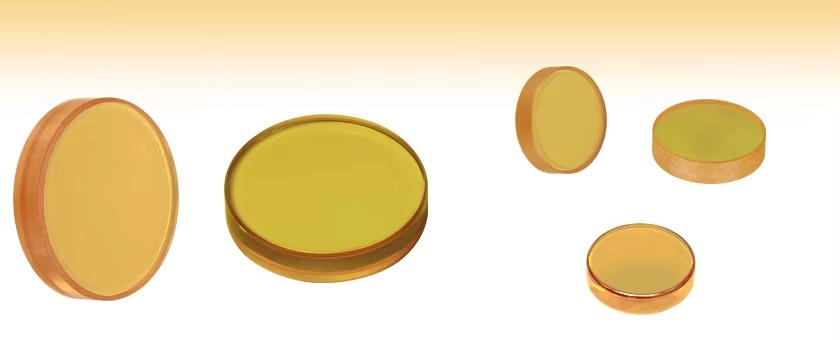

100 mm diameter with AR coated/unCoated

- It is an ideal choice for high-power CO2 laser applications.

- Extremely low infrared radiation absorption.

- Good thermal shock resistance

- 3 to 12 µm Broadband IR AR Coating

- Soft zinc selenide material is not recommended for harsh environments

- Low dispersion and absorption coefficient

ZnSe optical windows are often used in Forward Looking Infrared (FLIR) and thermal imaging systems, and they can be used as resonator windows in high power CO2 laser systems at 10.6 microns. Zinc Selenide has a low dispersion and low absorption coefficient, and a density of 5.27 g/cm3. Its refractive index is near 2.4. It is non-hygroscopic, which means it won’t absorb moisture from the air.

ZnSe optical windows are often used in Forward Looking Infrared (FLIR) and thermal imaging systems, and they can be used as resonator windows in high power CO2 laser systems at 10.6 microns. Zinc Selenide has a low dispersion and low absorption coefficient, and a density of 5.27 g/cm3. Its refractive index is near 2.4. It is non-hygroscopic, which means it won’t absorb moisture from the air.

The Zinc Selenide ZnSe used in our windows is produced by a process called Chemical Vapor Deposition (CVD). This enables us to achieve the extreme purity needed for high powered optics: 99.999% purity. During the process, zinc vapor and H2Se gas react to form sheets of ZnSe on graphite susceptors. These polycrystalline ZnSe plates are then precisely tooled to form optical windows.

Zinc Selenide optical windows must be handled with extreme care due to the materials softness: the Knoop number of ZnSe is 105. These optical components are not suitable for harsh environment. This same softness, however, makes them resilient to thermal shock. They can withstand thermally demanding environments and are chemically stable. This gives them importance in many applications including medical, industrial, and defense imaging.

Handling and Cleaning of ZnSe Windows

Because of the softness of the material, you should only handle a Zinc Selenide window by its edges. Apply uniform pressure to avoid warping. The utmost caution should be used while cleaning ZnSe optics to avoid scratching the soft surface. Dust or lint particles can typically be blown off with a dust free blower or air bulb. If further cleaning is needed, acetone or isopropyl alcohol may be used to clean the surface. While holding the optic by its edges, gently wipe the surface with a damp cotton ball. Do not rub, and do not exert pressure. Use only surgical-quality cotton balls.

Zinc Selenide is toxic, and protective rubber gloves should be used whenever handling windows or lenses made of this substrate.

Sapphire window optical elements coated multi-size specifications Optical infrared window 12inch dia 300mm C-aixs Al2O3 Sapphire Wafer double side polished DSP Customized Size 8 inch sapphire wafer substrate