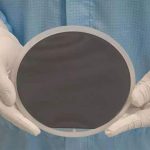

In semiconductor manufacturing, the physical perfection of silicon wafers isn’t just nice-to-have – it’s make-or-break. As features shrink to nanometer scales, even microscopic deviations in wafer shape can ruin devices. Terms like TTV, Bow, and Warp get thrown around constantly, but what do they actually measure, and why do they matter differently? Let’s cut through the jargon.

Why Flatness is Non-Negotiable:

Imagine projecting intricate circuit patterns (using photolithography) onto a surface that’s uneven. Light focuses at different depths, blurring patterns. Later process steps like chemical-mechanical polishing (CMP) or bonding wafers together require intimate, uniform contact. A warped wafer simply won’t cooperate, leading to defects, device failures, and scrapped material. Different tools and processes stress different flatness aspects.

The Key Parameters Demystified:

TTV (Total Thickness Variation):

What it is: Measures thickness inconsistency across the entire wafer. It’s the difference between the absolute maximum and minimum thickness points anywhere on the wafer.

How it’s measured: Probes (mechanical or capacitive) scan the wafer surface while the wafer rests on a perfectly flat chuck (which forces the backside flat). This isolates thickness measurement from shape deformation. Results are often visualized as a contour map.

Why it matters: Critical for processes requiring uniform depth control. CMP polishes material away; significant TTV means some areas polish too much (exposing underlying layers prematurely) while others don’t polish enough. It also impacts heat dissipation uniformity during processing and bonding integrity in 3D stacking. High TTV often points to issues in wafer slicing or grinding.

Think of it as: “How much thicker is the thickest part compared to the thinnest part, anywhere?”

Bow:

What it is: Measures the concave or convex deformation of the wafer’s median surface when it’s resting freely on a flat surface with no vacuum or clamping forces applied. It specifically looks at the maximum deviation of this median surface from a flat reference plane. It’s a global, symmetrical curvature, like a shallow bowl or dome.

How it’s measured: The wafer sits unrestrained on three fixed points defining a reference plane. A sensor measures the height of the wafer’s center point relative to this plane. The value is typically reported as positive (concave, center down) or negative (convex, center up).

Why it matters: Primarily caused by intrinsic stress gradients through the wafer thickness (e.g., from epitaxial layer growth, film deposition on one side, or thermal history). Excessive bow makes automated handling difficult (robots struggle to pick it up cleanly) and can cause focus issues in lithography scanners if the wafer doesn’t sit predictably on the chuck. It can also indicate underlying stress that might lead to problems later.

Think of it as: “How much does the center sag or bulge when the wafer is just sitting loose?”

Warp:

What it is: Measures the non-uniform deformation of the wafer’s median surface when it’s resting freely (like Bow). It’s defined as the difference between the maximum and minimum deviations of the entire median surface from a defined reference plane. Unlike Bow’s simple curvature, Warp captures any irregular, non-symmetrical bending or twisting.

How it’s measured: Similar setup to Bow measurement (free state on reference points), but multiple points across the entire surface are measured to map the deviation. The result is the peak-to-valley distance of this mapped surface relative to the best-fit reference plane.

Why it matters: Warp indicates complex, non-uniform stresses within the wafer. This is often caused by pattern-dependent stresses (e.g., dense vs. sparse circuit areas creating localized stress after film deposition and etching) or significant thermal gradients during processing. Severe warp causes major handling problems, local focus failures in lithography, and alignment issues. It’s often the trickiest to correct.

Think of it as: “How much does the entire wafer surface twist, bend, or ripple irregularly when it’s free?”

Site TIR (Total Indicated Reading) / Site FPD (Focal Plane Deviation):

What it is: Measures flatness locally, within a small, defined area (a “site”) that corresponds to the exposure field size of a photolithography stepper/scanner (e.g., 26mm x 33mm). TIR is the peak-to-valley distance of the wafer surface within that specific site relative to the best-fit plane for that site only.

How it’s measured: Using specialized flatness metrology tools (like interferometers) while the wafer is typically held flat on a chuck (simulating lithography conditions). The tool divides the wafer into site-sized areas and calculates the TIR for each.

Why it matters: This is directly relevant to lithography performance. The stepper lens has a limited depth of focus (DoF). If the height variation within the area being exposed in one shot (the site TIR) exceeds the DoF, parts of the pattern will be out of focus and blurred. Lithographers obsess over site TIR maps.

Think of it as: “How bumpy is this particular small patch where the circuit pattern will be printed?”

SFQR (Site Frontsurface least sQuares Range):

What it is: An enhancement of Site TIR specifically designed for modern lithography. Instead of simple peak-to-valley (TIR), SFQR calculates the range of surface heights within a site relative to the best-fit least-squares plane for that site. This filters out some global tilt, focusing on local deviations that truly impact focus.

How it’s measured: Similar tools as Site TIR, but using a more sophisticated calculation based on least-squares fitting per site.

Why it matters: Provides a more accurate prediction of lithographic defocus than simple TIR by removing the component of the site’s tilt that the scanner’s autofocus system can easily compensate for. It’s the gold standard for advanced lithography flatness specs.

Think of it as: “After accounting for how tilted this small patch is (which the scanner can fix), how bumpy is it (which the scanner can’t fix)?”

Putting it All Together: The Hierarchy of Impact

For Lithography (Patterning): SFQR/Site TIR >> Warp > Bow > TTV. The local flatness within the exposure field (SFQR/Site TIR) is paramount. Global warp can cause sites to sit at different heights on the chuck, challenging the scanner’s autofocus range. Bow affects initial chucking but is often compensated. TTV has the least direct impact here.

For Bonding (e.g., 3D ICs): TTV >> Bow/Warp. Uniform thickness (low TTV) is critical to ensure voids don’t form at the bond interface across the entire wafer. Bow/Warp can make initial alignment and contact challenging but might be overcome by applied force.

For CMP: TTV >> Site TIR. Uniform removal requires consistent starting thickness. Local flatness (Site TIR) affects within-die uniformity.

For Handling & Metrology: Bow/Warp >> TTV. Severely bowed or warped wafers jam tools, break, or can’t be measured accurately. TTV doesn’t directly cause handling issues.

Key Takeaways in Plain English:

TTV = Thickness Lottery: Did you get a thick spot or thin spot? Bad for polishing and bonding.

Bow = Dome or Dish: Is your wafer shaped like a Pringle or a cereal bowl? Bad for handling and hints at stress.

Warp = Potato Chip: Is it twisted and wavy? Very bad for handling and getting everything in focus during printing.

Site TIR/SFQR = Local Bumpiness: How rough is just this little square where the circuit gets printed? Critical for sharp patterns.

No One Metric Rules: The “worst” parameter depends entirely on what you’re doing to the wafer next. Lithography cares intensely about SFQR, bonding screams about TTV, and your equipment operator curses Bow and Warp.

Understanding these distinctions is crucial for process engineers to diagnose yield issues, set realistic specs, communicate with wafer suppliers effectively, and ultimately, keep those nanometer-scale transistors printing perfectly. It’s the invisible foundation of making chips work.